News

Products & Equipment

Cranes

Specialized solutions for the wind energy sector

May 31, 2021 By Crane & Hoist Canada Staff

The replaceable inserts of the CrosbyIP pipe hook are made from soft steel to prevent contamination and marring. Courtesy of The Crosby Group.

The replaceable inserts of the CrosbyIP pipe hook are made from soft steel to prevent contamination and marring. Courtesy of The Crosby Group. The wind energy sector is one of the world’s most demanding industries, and those involved with the manufacturing and installation of towers, monopiles, and transition pieces can often face very unique challenges. However, the industry also faces similar elements to many other end-use industries, such as the need ifting heavy materials from various angles; concerns about damaging equipment during shipping and handling; and a top focus on safe lifting and rigging operations.

To accomplish and overcome the unique and common challenges faced in the wind energy sector specific equipment is necessary, including vertical and horizontal lifting clamps and pipe hooks.

What the wind sector needs

The wind energy sector has high standards for its applications and each piece of equipment needs to be in perfect condition leading up to installation. “When handling steel plates with lifting clamps, the clamping camsegment and pivot usually leave an indentation in the material surface, known as marring,” said Kees Gillesse, product marketing manager at The Crosby Group, which is a manufacturer of rigging, lifting, and load securement hardware. “Because of the high standards in the wind energy industry, these indentations have to be ground away from the surface, costing time and money.”

Oftentimes, the general solution is to have aluminum inserts to prevent marring of the surface of the pipe. However, aluminum can cause contamination in the steel of the pipe, compromising the quality of the weld, when welding pipe sections together.

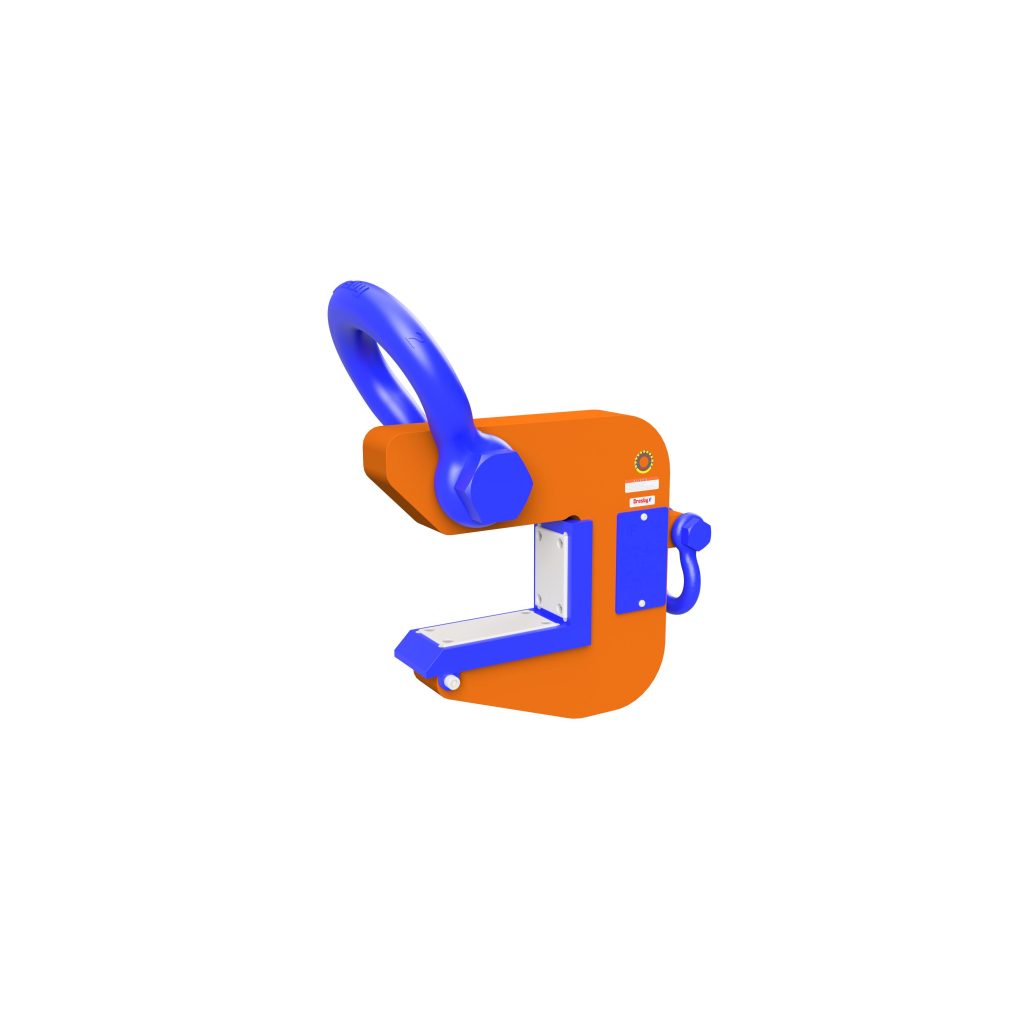

To meet the needs of the wind energy, The Crosby Group manufactures vertical and horizontal lifting clamps and pipe hooks, including minimal-marring camsegments and pivots. The vertical lifting clamps and hook pipes feature a welded steel body to minimize size and simultaneously increase strength and avoid contamination. “By reducing the height of the teeth in the camsegment and pivot, the pitch between the teeth can be decreased and more teeth can be in contact with the material surface, reducing the depth of the indentations,” Gillesse explained.

Specialized solutions for unique challenges

Specializing in custom designs for the wind sector, The Crosby Group have delivered a number of special clamps to meet particular needs, with a recent example being the 22.5t capacity special universal vertical clamp. The clamp, which was designed for a German wind energy manufacturer, included an extra-wide camsegment and three pivots for less surface pressure, to further reduce indentations. A deep jaw, meanwhile, allowed for lifting beveled plates and constructions. Lifting brackets made positioning easy when the lifting clamp was in the horizontal position. Additionally, the universal lifting eye permits lifting from every direction.

All clamps are manufactured at an ISO 9001-certified facility, and all sizes are RFID-equipped.

Print this page