News

Products & Equipment

Cranes

Deliveries

Liebherr debuts 700-tonne crawler crane at wind farm job

September 30, 2021 By Crane & Hoist Canada Staff

The heaviest tower segment of the Nordex wind turbine weighs in at a gross load of 70 tonnes. A Liebherr LTM 1250-5.1 mobile crane is helping the LR1700-1.0 (left) to erect the tubular tower. Photo: Liebherr

The heaviest tower segment of the Nordex wind turbine weighs in at a gross load of 70 tonnes. A Liebherr LTM 1250-5.1 mobile crane is helping the LR1700-1.0 (left) to erect the tubular tower. Photo: Liebherr Liebherr has released a new 700-tonne crawler crane, the LR 1700-1.0.

The crane made its debut on a wind farm job site near Paderborn, Germany. Local crane company Hofmann Kran-Vermietung GmbH & Co KG, a subsidiary of the Bracht Group, used the crane to erect a Nordex Delta 4000 wind turbine.

The LR 1700-1.0 dealt with the prefabricated 96-metre high concrete tower for the turbine with a hub height of 164 metres. The heaviest components were the nacelle and drive train with gross loads of 72 and 75 tonnes.

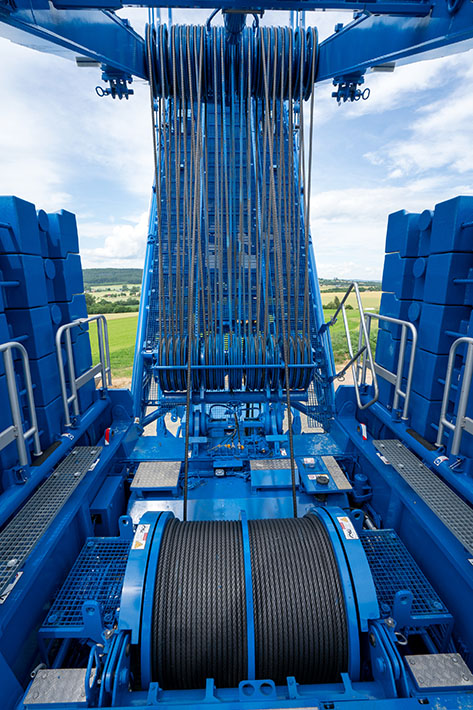

The LR 1700-1.0 was equipped with a 165-metre-long main boom. This includes nine lattice boom sections of the somewhat wider H (heavy) version, each 12 metres long.

“The H-boom lets us operate under higher wind loads,” says crane operator Christoph Bergmaier in a press release.

The greater wind tolerance of this boom configuration can save the crane and assembly teams on site from stopping due to excessive wind. Liebherr allows wind speeds of 11.2 metres per second for the LR 1700-1.0 – as for all current LR crane types with special wind power equipment configurations.

The twelve-metre fixed tip of the LR 1700-1.0 can handle a load of 170 tonnes, surpassing the capacities of the LR 1750/2. Here it is used for installation of the drive train with a gross weight of 75 tonnes. The design of this boom tip allows relatively generous manoeuvring of large components such as the nacelle just below the pulley head. Photo: Liebherr

With only a minimally reduced maximum load, this value even increases to 13.4 metres per second. Normally, the wind stops at nine metres per second.

“The VarioTray divisible derrick ballast and V-frame allow us to work with 60 tonnes of derrick ballast during the entire assembly of the turbine – so we don’t have to carry out any time-consuming ballasting,” says Bergmaier.

The large ballast pallet is only docked for erecting or taking down the lattice boom – which can be erected to a length of 198 metres. The procedure takes about 10 minutes with four bolts – and a total of 375 tonnes of counterweight is already hanging from the derrick boom.

The continuously adjustable V-frame ballast radius enabled the blue-painted Hofmann crane to operate in relatively little space on the construction site near Paderborn, even during the slewing process.

For the assembly of the wind turbine components at a radius of 26 metres, the two drivers then steered their crawler crane close to the tower. The crane also handled the heaviest loads on the hook – the 72-tonne nacelle and the three-tonne drive train – without issue.

Check out some more images in the gallery below:

Print this page