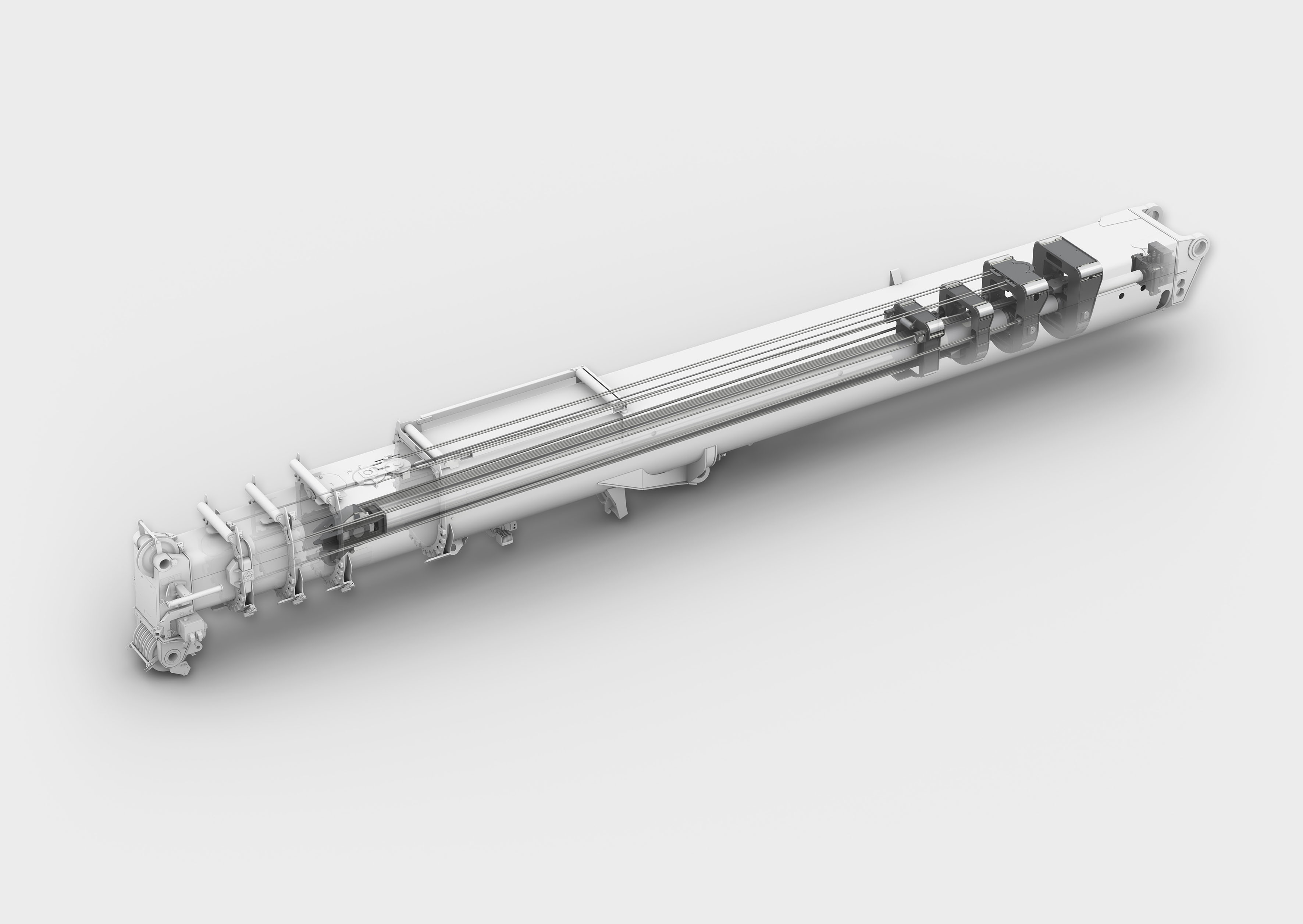

High-speed telescoping using rope extension mechanism. Photo: Liebherr

Boom with rope extension mechanism – familiar and fast

Crane contractors who chiefly use the Liebherr compact crane inside buildings and mostly do not need the full length of the 36-metre telescopic boom see also benefits of a boom with rope pull technology. Liebherr says the telescoping process is faster and many operators of mobile cranes in the lifting capacity class up to 50 tonnes are familiar with rope pull technology.

Liebherr uses a hydro-mechanical telescoping system on LTM mobile cranes whose telescopic boom consists of the pivot section and a maximum of three telescoping sections. The integral rope pull technology enables the telescopic boom to be extended to the required length particularly easily and quickly.

Liebherr decided to develop a boom with a rope extension mechanism as an alternative for the LTC 1050-3.1. This is 31 metres long and consists of a pivot section and 4 telescoping sections – one less than the TELEMATIK boom.

The telescoping sections are extended and retracted using a dual-action 2-stage hydraulic cylinder. Stage 1 extends telescoping section 1. Stage 2 extends telescoping sections 2 to 4 synchronously using a 2-way pulley block. The new boom also delivers high telescoping lifting capacities, an important feature for use inside buildings.

LTC 1050-3.1 with TELEMATIK boom and rope extension boom (right). Photo: Liebherr

LTC 1050-3.1 with TELEMATIK boom and rope extension boom (right). Photo: Liebherr