Features

Education & Training

Technology

Evolving 3D modelling

Crane companies are choosing one software in overwhelming numbers

December 13, 2023 By Matt Jones

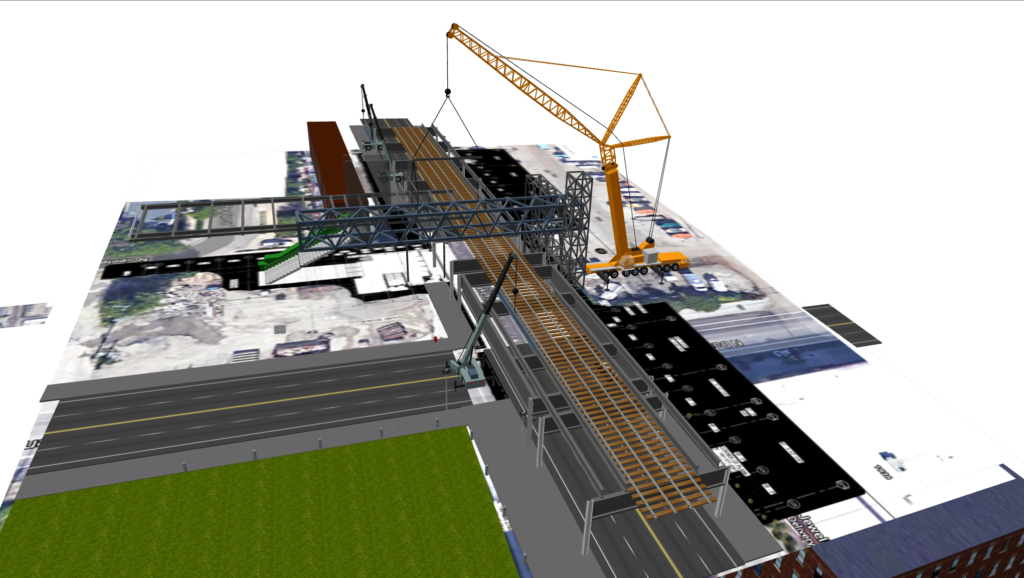

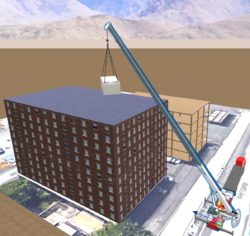

(Photo credit: A1A Software)

(Photo credit: A1A Software) 3D modelling for crane operations planning has come into its own in the last few decades. For many years, Computer-Aided Drafting (CAD) programs were the standard in the crane industry and continue to be used around the world.

But in the mid-2000s 3D modelling started gaining popularity in North America and one of the first products that hit the market in that space was A1A Software’s 3D Lift Plan program. Since then, A1A have become one of the standards in the industry, and Vice-President of Sales and Marketing Bruce Kabalen says that 91 of the top 100 crane companies use their products every day.

Kabalen spoke with Crane & Hoist Canada about the company’s suite of products and how they have evolved alongside the crane industry and technology.

3D modelling has become a crucial part of the industry, and programs such as 3D Lift Plan are key to that.

“Technology and time have made our products indispensable in the industry,” says Kabalen. “We have the largest database of crane lift charts in the world with over 2,000 cranes and growing each day. Our products have evolved with changes to internet browsers, and we now offer an app that doesn’t require the browser to function.”

Kabalen says that the A1A Product Suite dissects their core product – the 3DLiftPlan.com website – into role-based programs for users, which offers a variety of applications. SketchPad allows salespeople to plot a jobsite quickly with imagery of the job site so they can begin the lift planning process. Rigging Designer allows users to begin pre-engineered rigging, below the hook, and to customize their specific needs with slings and spreader bars. 3D LiftPlan gives the user the features and accessibility of the website but optimized for a laptop or tablet without the need for a browser.

“3D LiftVision [the final element of the A1A Product Suite] is a revolutionary program that works only with our new 3D LiftPlan app and allows users to immerse themselves and customers into the cab of any crane and jobsite they have created in 3DLiftPlan,” says Kabalen. “With the use of virtual reality (VR) headsets and joysticks, users can operate the crane in the ‘real’ environment they have created. This is a gamer changer in that customers can see critical lifts before they happen, and operators can practice the lift before they come to the jobsite. All this makes the lift safer and more efficient and provides instant feedback on crane and rigging selection before costly mistakes happen.”

Kabalen says that for A1A’s 20-some employees the biggest part of putting together such software is compiling all the possible information – having the exact dimensions of cranes, all the critical components (carrier, boom, extensions, outriggers, counterweights) and jobsite obstructions such as buildings, fences or other pieces of construction equipment.

“We are in daily contact with our customers and crane manufacturers on changes to their products and adapt accordingly,” says Kabalen on how they stay current. “We also adapt our delivery devices. When browsers no longer allowed for plug-ins that we used we had to change our entire 3DLiftPlan generation engine to comply with the changes. This is the same reason we have developed our A1A Product Suite, ensuring that if browsers as we know them go away, our products continue to work for our customers.”

Kabalen notes that continuing to meet their customers’ needs with development and updates is the biggest challenge for A1A Software today. Data collection and distribution is always a challenge as they continue to add new cranes and charts as they are released by manufacturers and requested by their customers.

CAD programs are still employed in some areas, most notably in Europe. But Kabalen notes that the advantage that their software brings is that it is much more accessible. Properly operating CAD programs generally involves understanding a large volume of commands and options which can be extremely daunting to users and could require some specific training. A1A’s suite of software is designed to be more user-friendly.

“I think a lot of Canadians and Europeans use a lot of CAD stuff, but they have to have the ability on their staff to do that and that sets us apart from day one,” says Kabalen. “And then the accessibility on the web for us, initially, was a big plus. The simplistic nature of our program lets little crane companies look like the big guys. That’s been a really good thing for the industry, I think.”

A1A are looking to leverage their products to achieve more market penetration into areas like Europe. In particular, Kabalen hopes that 3D LiftVision will open some doors in other markets.

In addition to modelling, Kabalen hopes his software’s features can drive the platform to also be seen by the crane industry as a valuable training tool.

“The crane people will use that from a risk-mitigation standpoint, but also in the training aspect,” says Kabalen. “Yes, there’s training simulators out there, but none of them really put you in an actual real-life setting. And that’s the difference for us. You can say there’s other simulators that teach operation, but that’s not really what we’re after. We’re going to get some of that as a byproduct and a lot of it is going to be where people want real life experience on a job site and that’s a close as physically being there as you can get.”

Looking to the future, Kabalen says that A1A are interested in potential applications for augmented reality (AR) systems – where rather than presenting an entire virtual environment as in VR, AR allows the overlay of graphics and information over the real world. The most common applications of such technology have been on the maintenance side, for example providing guidance to a mechanic as they repair a complicated piece of machinery. A1A Software’s lead developer has previous experience developing AR systems for the U.S. government.

“It’s not on our development plate for next year,” says Kabalen. “But it is on the drawing board.”

Print this page