Features

Cranes

Safety & Risk Management

Top climbing a tower crane: Ensuring safe assembly and dismantling

October 14, 2021 By WorkSafeBC

Top climbing a tower crane: Ensuring a safe assembly and dismantling. Image: WorkSafeBC

Top climbing a tower crane: Ensuring a safe assembly and dismantling. Image: WorkSafeBC The potential for tower cranes to be hazardous is well known, and has been brought to the forefront in recent months when a catastrophic failure occurred during the dismantling of a tower crane on a construction site in Kelowna, B.C.

WorkSafeBC has released a new bulletin reminding employers and operators about the risks associated with assembling and dismantling cranes. The bulletin is entitled “Top climbing a tower crane: Ensuring safe assembly and dismantling.”

Top climbing is a common way of assembling, dismantling and repositioning a tower crane. This is potentially hazardous work that must only be performed by an experienced and competent lead hand and qualified workers.

The bulletin provides an overview of top climbing, discusses the hazards, employer responsibilities, safe work practices, and legal and regulatory requirements in B.C. Most importantly, it reminds employers that failure to follow the manufacturer’s instructions may result in a structural failure that puts lives and property at risk.

How top climbing works

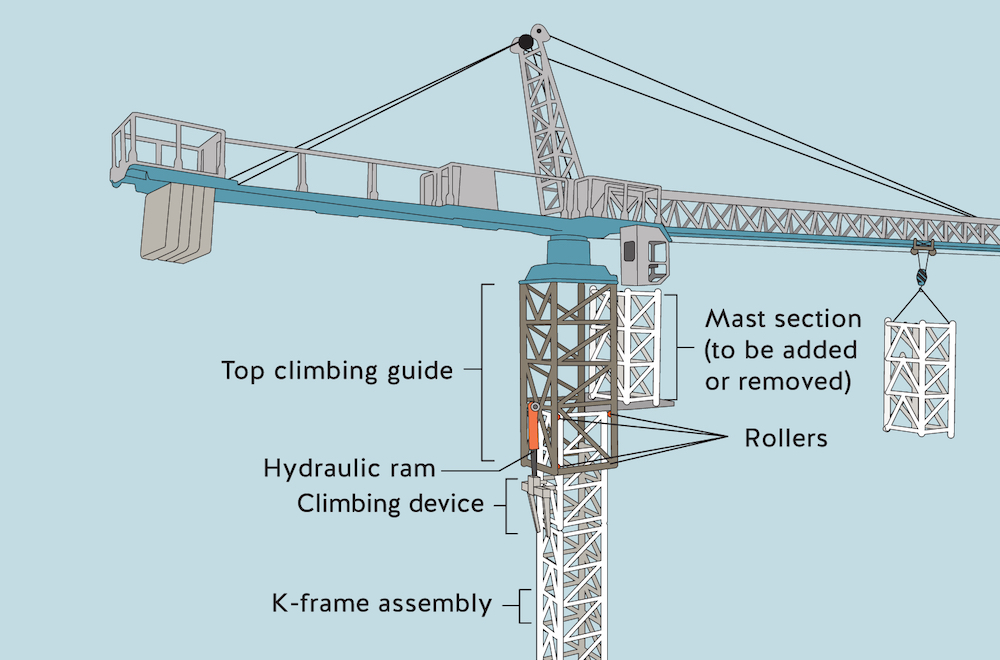

Top climbing is a common way of assembling or dismantling a tower crane on a construction site. A top climbing guide is a structure that is installed around the tower crane’s mast. The guide is used to create a gap for adding or removing mast sections.

Rollers are located at the middle and bottom of the top climbing guide on all four corners. When the system is weight-balanced, the rollers allow the guide to travel smoothly up and down the mast.

The top climbing guide includes:

- A hydraulic pump and ram

- A climbing device made up of a support shoe and a climbing traverse or cross-member (depending on the manufacturer)

The guide uses these parts to climb up or down the mast. Workers operate the guide manually.

The mast sections include K-frame assemblies that provide horizontal supports for the climbing device to push on. The ram raises the entire upper structure of the tower crane. This creates a gap in the mast that allows a single mast section to be either added or removed.

What is the hazard?

If the climbing device is placed on a K-frame horizontal support that is too high up the mast structure, the ram can push the top climbing guide too high. In this situation, the rollers in the middle of the top climbing guide may be positioned above the top of the mast structure and be unsupported. This puts the top climbing guide and the upper structure of the crane at risk of collapse.

A crane collapse can harm workers, pedestrians, property and structures located within the toppling distance of the crane.

“With just under 300 cranes operating across British Columbia, it’s fair to say there is a crane being erected, dismantled or repositioned every day in the province,” says Doug Younger, a prevention field services manager at WorkSafeBC who oversees the crane and mobile equipment initiative. “Failure to adhere to just one step in the correct assembling or dismantling process has catastrophic potential.”

Responsibilities

Employers must ensure that the tower crane erector, lead hand are experienced and competent in all aspects and each phase of top climbing process.

Workers engaged in top climbing activities must be:

- Qualified

- Provided with information, instruction, training and supervision to perform their work safely

Prime contractors must ensure that employers, supervisors and workers perform their work in compliance with these requirements.

Records should be requested to confirm the assembly supervisor’s and workers’ training and experience on the specific make and model of crane.

In some cases, a crane may be operated at the same time and in the same location as other work activity. In these situations, the employer or prime contractor must organize and coordinate the work of everyone on site so that the crane operation can be carried out safely.

Safe work practices

The assembly supervisor and workers must follow the tower crane manufacturer’s procedures. These procedures include placing the climbing device on the appropriate K-frame horizontal support.

Instructions and procedures for tower crane assembly, dismantling or top climbing must be established before such operations begin. The instructions and procedures must be adapted to the site conditions and communicated to all workers involved in top climbing operations.

Kelowna tower crane collapse

As a result of the tower crane collapse in Kelowna in July 2021, five people were killed, including four workers and a person unrelated to the construction site. Another worker was injured.

WorkSafeBC’s OHS Investigations team is currently investigating the tower crane collapse, and is working with subject-matter experts and engineers to examine the crane components, sequence of events and work procedures that took place during the dismantling process.

An incident investigation report will be prepared at the conclusion of the investigation.

This article appears in the upcoming issue of Crane & Hoist Canada.

Print this page