Features

Ports

Here’s how to combat crane cracks and fatigue

March 22, 2022 By Bill Tremblay

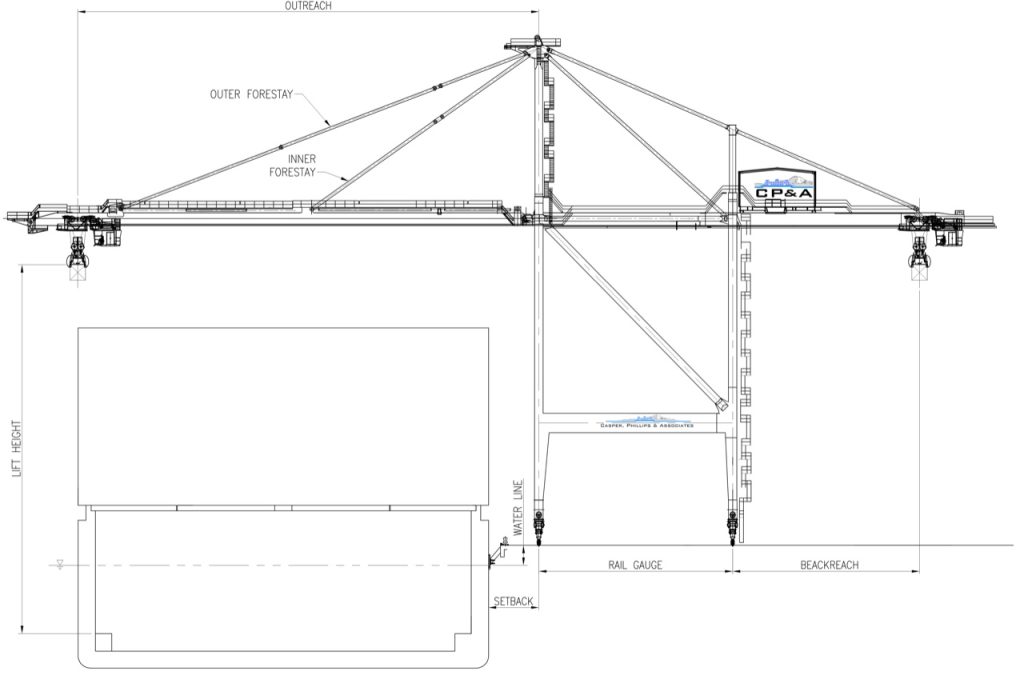

Stress concentrations on a container crane forestay led to crack formation. (CPA image)

Stress concentrations on a container crane forestay led to crack formation. (CPA image) Ports are pushing their container cranes harder for longer, which can lead to crane cracks and other fatigue-related issues

By Richard Phillips, mechanical engineer, Casper, Phillips & Associates (CPA)

Lately, it seems ports are delaying crane purchases and want to use their existing cranes past their design life. As well, cranes have been pushed harder than ever as they move record amounts of container traffic.

These two factors have led to an increase in maintenance issues related to fatigue on older container cranes.

Although steel can have an infinite design life in low stress environments, designing cranes to have infinite life would increase the cost to the point where it is not competitive.

Container cranes 20 years ago did not service ships as large as they do today, so it was unheard of to have a crane with an outreach of more than 61 metres. Back then, the largest cranes could pick up a single 40 ft. or twin 20 ft. containers, whereas today the largest cranes can lift tandem 40 ft. containers or four 20 ft. containers.

Many people think of fatigue as “wearing out” of the steel but this is not quite right. Fatigue failure occurs in components subject to a high number of fluctuating stresses. Under these conditions, it is possible for failure to occur at a stress level significantly less than the tensile or yield strength for a static load. If the fluctuating stress is low enough and in an ideal environment, steel has infinite fatigue life.

RELATED: B.C.’s unique Crane Operator Certification Program

Cracks can initiate from many sources, such as high cycle fatigue, poor manufacturing, corrosion, or overload events such as snag, earthquake, or storm winds. The initial flaws may be microscopic or macroscopic. Growth rate increases with crack size so a flaw that has grown from microscopic to a detectable size is well along toward reaching critical size. However, if the steel lacks reasonable notch toughness, the critical crack length will be significantly smaller than steel with excellent notch toughness.

It’s unlikely that someone without training would be able to detect the first signs of cracking or fatigue. It is also unlikely an operator would notice a change in the performance of the crane, even if they are very familiar with it.

Fatigue and corrosion failure of container cranes have been rare, but there has been at least one incidence of total collapse and several close calls where imminent failure was avoided because cracks were discovered just in time. Numerous fatigue failures of individual members and connections have occurred but usually loads shift to an alternate load path, avoiding total collapse. Therefore, alternate load paths are an important fatigue design consideration.

Managing cracks

Just how critical is the problem when cracks appear? The answer depends on how much damage the area can safely withstand and the consequences of its failure. Damage due to a crack is directly related to how fast the crack can grow. The study of crack propagation is known as fracture mechanics, which combines analytical methods with experimental research to quantify a crack’s growth potential.

The consequences of a member or joint’s failure also plays a part in determining the criticality of a crack. A member or joint that has no alternate load paths and whose failure would cause a crane to collapse is called fracture critical.

Within fracture mechanics, one methodology to manage cracks and other defects is using damage tolerance. Pioneered by the aerospace industry, the idea behind damage tolerance is the engineer assumes there is a crack of the smallest size with a given inspection method. From there, the engineer can calculate the crack growth rate that will occur during normal use. This analysis is then used to set the appropriate inspection intervals based on the criticality of the member or joint. By calculating the crack damage tolerance of a crane and implementing the resulting inspection program, chances are much better that repair work can be identified and scheduled to minimize operational down time.

Container crane design

Design specifications for container cranes have been developed by consulting engineers, port authorities, and shipping companies. The specifications usually require the design of various elements comply with domestic and international design codes.

A consultant is often hired to validate if the crane structure and its components meet the specification requirements. The consultant must have engineering expertise and knowledge of local and foreign codes. Ensuring a crane design meets the design specifications reduces the risk of structural failures by ensuring appropriate materials and loads are used.

Unlike other industries, the container crane industry has no formal body for investigation, documenting or reporting structural failures. These failures are often a source of embarrassment, liability, or litigation and therefore remain confidential. If an accident occurs, disputes are usually settled through private litigation.

Best practice is to prevent accidents, so it is always a good idea to have a qualified engineer review the crane manufacturer’s design before construction, as well as having a good maintenance program once the crane is in service.

Another vital point to consider is corrosion. Of course, container cranes exist in a relatively hostile environment surrounded by saline and acid laden air. Techniques and materials for preventing corrosion are well known and the failure to maintain a corrosion-free crane is tantamount to accepting a reduced life for the affected crane components.

Life extension

In this current economic environment, there is uncertainty surrounding steel fabrication. Steel prices, component availability, labour prices, and workforce availability are all volatile. Crane owners want to protect themselves by procuring cranes on a firm fixed fee contract. Such a contract includes all costs associated with crane procurement including delivery and commissioning for a single price. Likewise, crane manufacturers protect themselves by building in costs due to the uncertainty surrounding steel fabrication.

This has further increased the number of crane owners taking interest in extending the life of cranes. A crane may have been designed for 2 million cycles, but the crane owners want to study the business case for upgrading the crane structurally and mechanically to extend the life up to three or even four million cycles.

As cranes are used beyond their original design life structural strengthening is a common method to extend the useful life. If a critical area has been properly strengthened, it will be less likely to develop cracks and will require less frequent inspections.

Crack repair

If a crack is detected it can be repaired. However, due to residual stresses, and other limitations from the on-site crack repair, detectable cracks may re-develop after fewer load cycles. If cracks are found, further engineering analysis should be conducted to determine what repairs should be made, plus due consideration should be given to increased inspections and possibly reinforcement. The most common fix for cracks is to grind out and weld repair them. Remember though, the best solution is prevention.

The most important defence against structural aging is targeted inspections performed at specified intervals. Of course, operators and maintenance personnel should be trained to inspect constantly at every opportunity. However, this should not replace inspection by trained technicians working at known intervals.

Periodically, all cranes should be examined by a technician with broad, generic experience with structural maintenance problems. Dangerous cracking and deterioration can escape even the most conscientious visual inspection. A sizeable fatigue crack can close so tightly it may not be visible to the naked eye even if known to exist. The only reliable way to find fatigue cracks is by non-destructive testing (NDT) methods by a qualified technician.

An engineered inspection manual can tell inspectors where and how often to look for cracks. A good inspection manual will show which NDT tests to run on the welds most likely to have fatigue cracks develop. For container cranes, maintenance windows are available in between berthing vessels. During this time, the cranes are not in service, and NDT can be performed. The inspection methods most used are visual, magnetic particle, or ultrasonic, and will depend on how critical the member is to the load carrying capacity of the crane.

Inspection by outside technicians is expensive but can save property and lives. Like all other risk/benefit alternatives, there is no universal answer to how much one should spend to reduce risk. The key to getting the best life out of these cranes is to have a good inspection manual and a responsive maintenance program. Creating post design life structural inspection manuals is a widely accepted service many crane owners currently utilize. Discovering a crack early can not only limit the scope of the repair but also limit unscheduled downtime.

Print this page